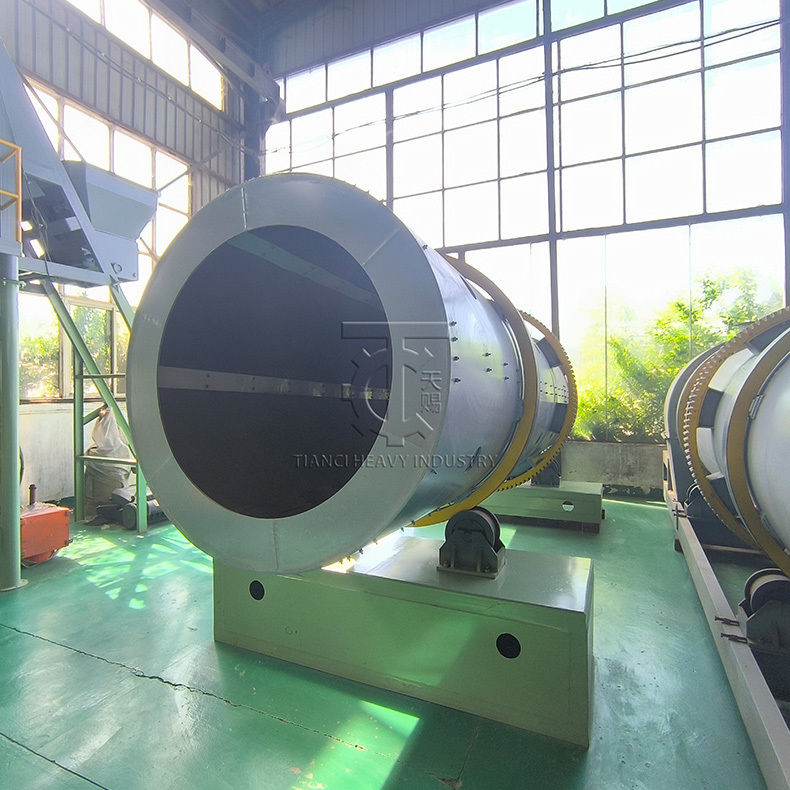

Döner tamburlu granülatör ürün açıklaması

Döner tamburlu granülatör, toz halindeki malzemelerin granülasyon sürecinde yaygın olarak kullanılan temel bir ekipmandır ve özellikle gübre üretimi, maden işleme ve yapı malzemeleri alanlarında öne çıkmaktadır. Çalışma prensibi, mekanik dönme, malzeme yerçekimi ve yardımcı bağlayıcının birleşik etkisine dayanır: toz halindeki ham maddeler (örneğin, kompoze gübre hammaddeleri, mineral tozu vb.) eğimli dönen tambura sürekli olarak beslenir. Tamburun dönmesi sırasında, malzemeler sürekli olarak döndürülür, yuvarlanır ve çarpışır. Az miktarda bağlayıcı madde (veya bazı malzemelerin doğal viskozitesi) yardımıyla, toz halindeki parçacıklar kademeli olarak, eşit boyutta küresel veya düzensiz granül ürünler halinde birleşir.

Döner tamburlu granülatörün başlıca avantajları

Temel avantajlar açısından, döner tamburlu granülatör öncelikle ham maddelere karşı güçlü bir uyarlanabilirliğe sahiptir. Farklı nem içeriklerine (genellikle %20-%40) ve partikül boyutlarına sahip çeşitli toz halindeki malzemeleri işleyebilir ve granülasyon oranı genellikle %85 veya üzerinde tutulur, bu da ürün kalitesinin istikrarını etkili bir şekilde sağlar. İkincisi, büyük üretim kapasitesi ve düşük enerji tüketimi özelliklerine sahiptir. Büyük çaplı ve uzun tambur yapısı, sürekli büyük ölçekli üretimi gerçekleştirebilir ve birim ürün başına güç tüketimi, diğer granülasyon ekipmanlarına (disk granülatör gibi) göre daha düşüktür. Ek olarak, ekipman basit bir yapıya, kolay kullanıma ve bakıma sahiptir. Ana parçalar (tamburun iç astarı gibi) aşınmaya dayanıklı malzemelerden (yüksek manganezli çelik gibi) yapılmıştır, bu da uzun hizmet ömrüne sahiptir ve değiştirme ve bakım sıklığını azaltır.

Uygulama senaryoları açısından, döner tamburlu granülatör en yaygın olarak gübre endüstrisinde kullanılmaktadır. Sadece gübrelerin kullanım oranını (granül gübrelerin kaybolması ve topaklanması kolay değildir) iyileştirmekle kalmayıp, aynı zamanda mekanize gübreleme ihtiyaçlarını da karşılayan kompoze gübre, organik gübre, biyolojik gübre ve diğer granül gübreleri üretebilir. Maden işleme endüstrisinde, sonraki eritme veya nakliyeyi kolaylaştırmak için mineral tozunu granüle etmek için kullanılır. Yapı malzemeleri endüstrisinde, yapı malzemelerinin performansını iyileştirmek için çimento klinkeri, alçı tozu ve diğer malzemelerin granülasyonu için kullanılabilir.

Gerçek üretim sürecinde, döner tamburlu granülatör aynı zamanda iyi bir çevre koruma performansına sahiptir. Tamburun sızdırmazlık yapısını optimize ederek ve toz toplama sistemiyle eşleştirerek, granülasyon işlemi sırasında toz halindeki toz emisyonunu etkili bir şekilde azaltabilir ve modern endüstriyel üretimin çevre koruma gereksinimlerini karşılayabilir. Aynı zamanda, ürünlerin farklı ihtiyaçlarına göre, tamburun dönme hızını, tamburun eğim açısını ve bağlayıcı madde miktarını değiştirerek, bitmiş ürünün partikül boyutu ayarlanabilir, bu da güçlü bir esnekliğe sahiptir.

Ana Teknik Parametreler

|

Süreç

|

Ekipman Adı

|

Model/Özellikler

|

miktar

|

ana rol

|

|

Ham madde depolama

|

Ham cevher tozu silosu

|

50m³ kapasite, titreşimli besleme cihazı ile

|

2 adet

|

Sürekli tedariki sağlamak için bentonit cevher tozunu depolayın.

|

|

Ham madde taşıma

|

vidalı konveyör

|

Taşıma kapasitesi 20m³/saat, malzeme 304 paslanmaz çelik

|

3 adet

|

Kapalı malzeme taşımacılığını sağlamak için çeşitli cihazları bağlayın.

|

|

Kırma ve yabancı maddeleri giderme

|

Darbe kırıcı

|

İşleme kapasitesi: 20 ton/saat; incelik ayarlanabilir (200 mesh).

|

1 adet

|

Ham cevherdeki topakları kırmak ve taş ve metal yabancı maddeleri gidermek.

|

|

İçerik Karıştırma

|

Çift şaftlı paletli mikser

|

Etkili hacim 5m³, karıştırma süresi 3-5dk/parti

|

1 adet

|

Ham cevher tozunu su (bağlayıcı) ile karıştırın ve nemi kontrol edin.

|

|

Çekirdek granülasyon

|

Döner tamburlu granülatör

|

Çap 2,2m, uzunluk 6m, eğim açısı 3°-5°, dönme hızı 12-15dev/dak

|

1 adet

|

Malzeme yığılmasını sağlayın ve hedef boyutta parçacıklar oluşturun.

|

|

Granül kurutma

|

Döner kurutma fırını

|

Çap 2,4m, uzunluk 18m, sıcak hava sıcaklığı 200-250℃

|

1 adet

|

Mukavemeti artırmak için partikül nem içeriğini ≤%3'e düşürün

|

|

Soğutma

|

Soğutma silindiri

|

Çapı 2,0m, uzunluğu 10m, hava soğutmalı + sprey soğutmalı

|

1 adet

|

Kuruyan parçacıkların sıcaklığı 80℃'den oda sıcaklığına düşürüldü.

|

|

Eleme ve derecelendirme

|

Çift katmanlı titreşimli elek

|

Elek örgü boyutu: 2mm (alt katman), 6mm (üst katman)

|

1 adet

|

Nitelikli granülleri, geri dönen tozu ve büyük boyutlu topakları ayırın.

|

|

Bitmiş ürün depolama

|

Bitmiş Ürün Deposu

|

80m³ kapasite, otomatik ölçüm ve boşaltma cihazı ile donatılmış

|

2 adet

|

Nitelikli bitmiş ürünleri depolamak, sonraki paketleme ve taşımayı kolaylaştırır.

|

|

Çevre koruma tesisleri

|

Torbalı toz toplayıcı

|

20.000 m³/saat hava hacmini işler, ≥%99,5 toz giderme verimliliğine sahiptir.

|

2 adet

|

Kırma ve kurutma işlemleri sırasında oluşan toz, standartlara uygun olarak toplanır ve boşaltılır.

|

Müşteri Uygulama Örnekleri

Önerilen İlgili Granülatörler

|

|

|

|

| Tambur Granülatör |

Tava Granülatör |

Rulo Pres Granülatör |

Döner Tamburlar ve Pim Kombine Granülatör

|

Döner Tamburlu Granülatör Sıkça Sorulan Sorular (SSS)

S: Lütfen döner tamburlu granülatörünüzün saatlik çıktı aralığını belirtir misiniz?

C: Döner tamburlu granülatörümüzün standart saatlik çıktısı 1 ila 300 ton arasında değişmektedir. Daha yüksek çıktı talepleriniz varsa (örneğin, saatte 25 tondan fazla), özel üretim ihtiyaçlarınıza göre özelleştirilmiş bir çözüm tasarlayabiliriz.

S: DÖNER TAMBUR GRANÜLATÖR NASIL ÇALIŞIR?

C: Bir tambur granülatör, granül oluşumunu ve büyümesini teşvik etmek için malzeme bir sıvı bağlayıcı varlığında yuvarlayarak çalışır. Besleme malzemesi ve bağlayıcı, dönen tamburdan sürekli olarak beslenir. Yuvarlanma hareketi, bağlayıcının yapışkanlığı ile birleştiğinde, ince tanelerin bir araya gelerek parçacıklar oluşturmasına neden olur. Bu parçacıklar, yatakta yuvarlanırken ek ince taneler ve bağlayıcı toplamaya devam eder, bu da onların yoğunlaşmasına ve birleşme olarak bilinen bir olguda ek katmanlar almasına neden olur. Malzeme yatağının çalkalanmasını artırmak için üniteye yuvarlanma kanatları dahil edilebilir.

Bu şekilde aglomera oluşturma, ıslak granülasyon, topaklama veya peletleme olarak da bilinen bir tür çalkalama aglomerasyonudur.

S: DÖNER TAMBUR GRANÜLATÖR HANGİ TÜR MALZEMELERİ İŞLEYEBİLİR?

C: Genel olarak konuşursak, tambur granülatörler, kuru, ince toz halinde herhangi bir dökme katıyı işleyebilir. Bu esneklik, özel kimyasallar ve gübrelerden minerallere ve cevherlere ve aradaki her şeye kadar çeşitli malzemeleri işleyen çok sayıda endüstriye iyi gelir.

Bazı durumlarda, besleme stoğunun granülatör için uygun bir besleme olması ve son üründe istenen özellikleri üretmesi için kırma, öğütme veya kurutma şeklinde ön işleme tabi tutulması gerekebilir.

S: DİSK PELETLEME MAKİNESİNE GÖRE DÖNER TAMBUR GRANÜLATÖRÜN AVANTAJI NEDİR?

C: Bir tambur granülatör ve bir disk peletleme makinesi arasında seçim yaparken, tambur genellikle disk peletleme makinesinden daha yüksek bir verim sunduğu için seçilir. Döner tamburun ayrıca, granülasyonun kapalı bir ortamda gerçekleştiği anlamına gelen bir “kapalı” sistem olma avantajı vardır, bu nedenle kaçak malzeme sınırlıdır.

BİR GRANÜLASYON TAMBURU HANGİ KAPASİTELERİ KABUL EDEBİLİR?

C: Granülasyon tamburları, 500 lb/saat – 3500 TPH+ arasında değişen kapasiteleri barındıracak şekilde neredeyse her boyutta özelleştirilebilir.

TAMBUR GRANÜLATÖRLER PARTİ Mİ YOKSA SÜREKLİ Mİ?

C: Döner tamburlu granülatörler tipik olarak sürekli bir ortamda kullanılır, ancak TIANCI İnovasyon Merkezi gibi bazı Ar-Ge ortamlarında bir parti cihazı olarak işlev görebilirler.

S: DÖNER TAMBUR GRANÜLATÖRÜN TUTMA SÜRESİ NEDİR?

C: Tutma süresi, tamburdan çıkan malzemenin özelliklerini ve kalitesini kontrol etmek için kullanılan bir işlem parametresidir, bu nedenle işleme ve ürün hedeflerine bağlı olarak önemli ölçüde değişebilir. Genel olarak, bir granülatördeki tutma süresi 30 saniye ile 60 dakika arasında herhangi bir yere düşebilir.

S: TIPİK AŞINMA ÖĞELERİ NELERDİR?

C: Döner tamburlu granülatörler genellikle düşük bakım gerektirir, ancak bazı öğeler, çalışma koşullarına bağlı olarak ve özellikle tambur hizadan çıkarsa aşınabilir. Bir tambur granülatör için en yaygın aşınma öğeleri tipik olarak astarı (varsa), yuvarlanma kanatlarını (varsa) ve potansiyel olarak pabuç tekerleklerini, lastikleri ve itme silindirlerini içerir.

Tambur bakımı için, lastiklerin ve pabuç tekerleklerinin aşınmasını önlemek için döner tambur hizalaması önemli bir husustur. Bir tambur hizadan çıktığında, tüm bileşenlere ek stres uygular ve gereksiz aşınmayı teşvik eder.

S: GRANÜLATÖRDEN ÇIKAN ÜRÜN KURUTMA GEREKTİRİR Mİ?

C: Granülasyon işlemi, granülleri oluşturmak ve katmanlamak için bir sıvı bağlayıcıya dayandığından, granülatörden çıkan ürün ıslaktır ve kurutma gerektirir, kurutma gerektirmeyen bir sonraki bir işleme hemen geçmiyorsa (peletlerin bir ızgara fırınına gittiği demir cevheri topaklama durumunda olduğu gibi).

Kurutma tipik olarak, tamburun dönmesi sonucu meydana gelen yuvarlanma hareketi sonucunda granülleri daha da yuvarlayan ve “parlatan” bir döner kurutucuda gerçekleştirilir.

S: BİR DÖNER TAMBUR GRANÜLATÖRÜN UYGULAMAM İÇİN DOĞRU OLUP OLMADIĞINI NASIL BİLEBİLİRİM?

C: Bir döner tamburlu granülatörün belirli bir proje için doğru olup olmadığı, kapasite, partikül özelliklerinin kontrol düzeyi, ürün parametreleri ve daha fazlası gibi belirli işlem ve ürün hedeflerine bağlıdır.

Bir tambur granülatörün proje hedeflerini karşılayıp karşılayamayacağı net olmadığında, işlemi değerlendirmek ve en uygun ekipman konfigürasyonunu belirlemek için TIANCI İnovasyon Merkezi'nde testler yapılabilir.

S: BİR DÖNER TAMBUR GRANÜLATÖRÜNÜ DESTEKLEMEK İÇİN BAŞKA BİR EKİPMAN GEREKLİ Mİ?

C: Tambur granülatörler, malzemeyi tambura ve tamburdan taşımak için bir besleme ve alma sistemine ihtiyaç duyar. Ayrıca tipik olarak, fazla ve eksik malzemeleri geri kazanmak ve bunları işleme geri döndürmek için eleklere ve bir geri dönüşüm devresine ihtiyaç duyarlar.

Tambur granülatörleri ayrıca tipik olarak bir döner kurutucu tarafından takip edilir ve bazı durumlarda, üniteye homojen bir besleme stoğu sağlamak için bir karıştırıcı tarafından önceleyebilir.

S: TASARIM SÜRECİ NASIL GÖRÜNÜYOR?

C: Döner tamburlu granülatör tasarımı tipik olarak, amaçlanan malzemenin granülasyonunun fizibilitesini değerlendirmek ve dolum yüzdesi, tutma süresi, tambur hızı ve eğimi, püskürtme sistemi tasarımı ve daha fazlası gibi temel işlem verilerini toplamak için testlerle başlar.

Veriler toplandıktan sonra, mühendisler bunu tamburu boyutlandırmak ve istenen kapasitede istenen ürünü üretmek için gerekli olan tüm özellikleri veya değişiklikleri dahil etmek için kullanırlar.

S: BİR DÖNER TAMBUR GRANÜLATÖRÜ TASARLAMAK İÇİN HANGİ VERİLERE İHTİYAÇ VAR?

C: Granülatörü tasarlamak için çeşitli veri noktaları gereklidir. Bir işlem açıklamasıyla birlikte, aşağıdaki veriler tipik olarak gereklidir:

Neden Bizi Seçmelisiniz?

Destek ve Hizmetler:

Müşterilerimize kapsamlı destek ve güvenilir hizmetler sunmaya kararlıyız. Şirketimiz, ihtiyaçlarınıza göre uyarlanmış ücretsiz proses tasarım çizimleri ve ayrıca optimum makine performansını sağlamak için ücretsiz deneme test hizmetleri sunmaktadır. Her makine, sorunsuz çalışma için bir yıllık garanti ile birlikte gelir. Ek olarak, ekibinizin ekipmanı hızla ustalaşmasına ve verimli üretime ulaşmasına yardımcı olan ücretsiz kurulum ve profesyonel eğitim hizmetleri sunuyoruz.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!